During the Electronics & Applications 2017 fair on 1st of June Jack van Daal from RENA Electronica has given a peek inside of the process RENA is going through in her way to set up a Smart Factory. RENA is investing money and time to adjust the production facility to be able to serve their customers cheaper, better and faster.

Complex

This is not an easy task according Jack’s presentation during the seminar. Integrating to a Smart Factory is a process much more complex than just buying high-tech equipment able to produce automatically with the ability to correct automatically when failures occur. To set up a Smart Factory it’s critical that the knowledge available in the company has a very high level for both analytical, process and IT know how. If one of this knowledge’s is at a low level, the integration of Smart Factory will become a failure.

Analysis of good or bad

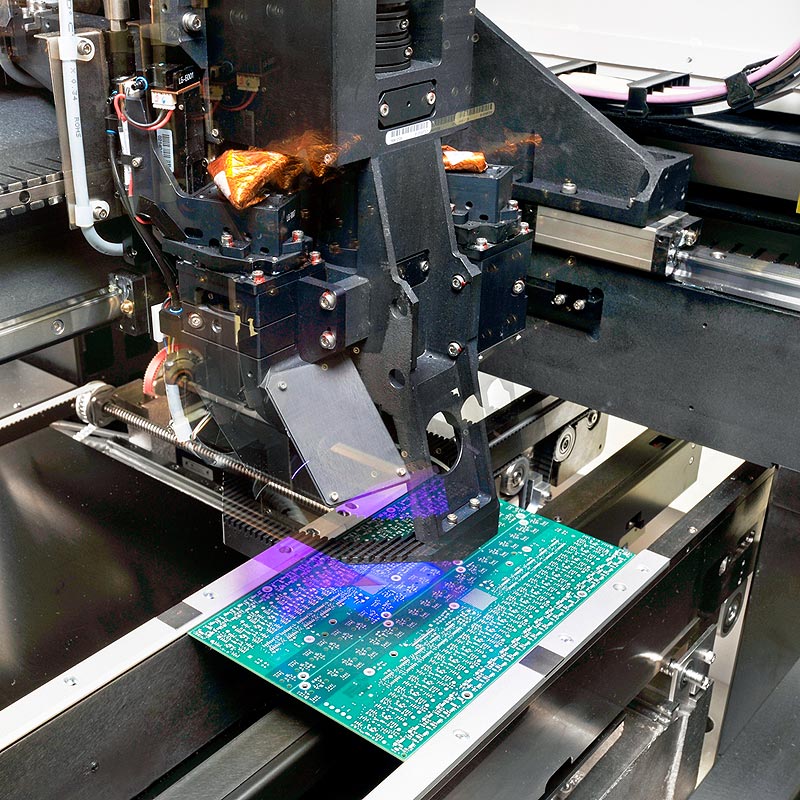

In a Smart Factory set up machines will be used (like Solder Paste Inspection and Automatic Optical Inspection) to analyze and even automatically adapt changes to the production process. These machines are smart for sure but the analysis of good or bad has to be taught. So if the knowledge of the process and analytics is below level, it will be impossible to define failures in the production resulting in programming a wrong threshold in the machine software. The machine itself will perform the process it’s taught in an automatic way.

The ultimate goal of a Smart Factory is to reduce the labor cost in the production process and to increase the level of performance to become competitive to production facilities based in countries where the wages are low. The machinery of the production line will produce at a same level of cost equal all over the world, the difference in total cost will be made in labor cost which will be higher in western countries in comparison to eastern countries.

Quality is key

In a Smart Factory quality also will be key. Quality should be constant and quantifiable. The continuity should be held high by the inspection equipment where these machines will automatically adapt changes to the process when structural failures are detected. Individual failures should be recognized and expelled to a reject conveyor without adapting changes to the line process (imagine missing components or wrong placed components).

Besides continuity the quality should be measurable and even be reducible. Identification by barcode is critical. At all times it must be reducible which components and what line setup is used to produce the typical PCBa. With this knowledge it’s possible to define which boards out in the field are affected with a structural failure so customers can call in these products before major problems will occur (imagine components produced out of spec which could lead to circuit changes when exposed to changing environmental aspects).

Rewarding

RENA has left behind a big part of the integration steps to become a Smart Factory but they didn’t reach the final goal yet. Even though the results of the current production facility are at a tremendous higher level which is also noticed by our customers. Our customers have noticed the changes we made and are rewarding us for the result.

They are rewarding us for following positive aspects:

- Leading and performing on technological base

- Much more competitive worldwide regarding cost price

- Shorter time to market

- More constant in quality

- Much more flexibility