We often say: RENA has a one-stop-shop concept with many benefits for the customer. But what does it actually mean and what does it mean for our customers? Our general manager Jochem Winkelman is happy to tell you more about it.

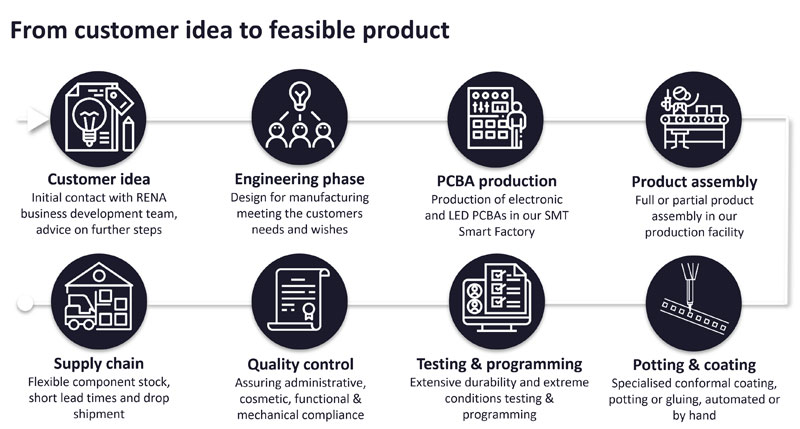

"What it comes down to is that you can accommodate everything from idea to product with us,” Jochem begins. “We have our own in-house engineering department and create all our products ourselves. As a result, our customers only have one party as a point of contact. We seek partnerships with our customers and think along in all aspects. This makes the production and development of electronics and lighting easier, more efficient and more effective. With us, customers can trust that their idea will be realized according to the specs, delivery time and quality they want. ‘Relieving the burden’ of the customer may sound like a cliché, but that is exactly what we do."

Outsource everything to one party

"We house all necessary capabilities to guide our customers from nothing to something, from idea to realization. Our customers often have a specific wish, but cannot get it onto the market with their own resources. They start looking for a party to outsource this and soon end up with RENA", Jochem says.

Solutions for extreme (weather) conditions

"A good example is the development of airport lighting for a long strip in the north of Scandinavia. This lighting must be able to withstand extreme cold, moisture, snow, dust and other harsh conditions, and may never stop functioning unexpectedly", the general manager says. These are requirements which don’t match with standard solutions that are on the market. That is why this company came to RENA.

"And then it starts for us", says Jochem enthusiastically. "We start with product development; we translate the idea into specifications and functional design, which we put together into a prototype. Every product goes through a standardized development process with us. We have been very experienced in this process through our 40 years of business, so we know exactly which steps to take."

Choosing components

This is how RENA realizes an idea together with the customer. Jochem continues: "We don’t only go through this with the technical side of the story, but also with project management and production in mind. We look closely at the cost price, which is one of the specifications that we determine in advance with the customer. The design strongly depends on which components we are going to use. We advise clients honest and straight about the consequences and feasibility of their idea. You may want a Maserati for the price of a Fiat, but the question is what you’ll get in return. We take good care of this step with the customer, we really see a collaboration as a partnership."

Where does the one-stop-shop stop?

Ultimately, the LED lighting produced must of course be installed at that airport in Scandinavia that we talked about before. "We’ve made a choice of not providing installation. We are rather a one-stop-shop in product development, design for manufacturing and production. That is what we are good at. Our customers can buy a solution that is tangible. And if problems arise, our customer has just one party where he can ask all his questions."

Why partial solutions are not an option

RENA's customers want one solution, instead of all kinds of separate partial solutions. Jochem thinks: "Creating a partial solution is basically creating a problem. Because in doing so, you present the problem back to the customer. Every time there's a change in design, finish or production, you need a different party. You constantly have to go back to the design phase. In this situation, the customer will have to deal with at least two parties and their coordination costs. This is very error-prone and also inefficient, slow and expensive. We have all aspects in-house so that a small change is easy to realize. Our engineering department is located right next to production. If there’s a problem, they’ll just walk right in.”

Version management, new features and end of life management

It's also easier to depend on just one party to keep products up-to-date. "If new components or techniques become available that are of interest to the customer, we can work with them to release a new version of the product. In addition, we arrange everything up to end of life management. It sometimes happens that a product can’t be produced because components are no longer available. If this happens, we’ll facilitate a redesign with different components, together with the customer. New features or modernization of the product portfolio are also possible. We regularly equip existing applications with WiFi, Bluetooth or new software."

Solutions without worries

"Our customers can obtain a turnkey solution without having to play an active role in the design or production themselves. So you can entrust all facets of the development of a product to one party. There is a lot more to it than you might think: in addition to development and production, you also have to think of certification, life cycle management, design verification and much more. We like to completely unburden our customers so that they can focus on what they are good at.

Our goal is to take away the worry for the customer of developing a product themselves. If RENA seamlessly meets the customer's wishes, then we have done our job well."

Would you like to worry as little as possible about the development and production of a new or existing product too? Feel free to contact us!