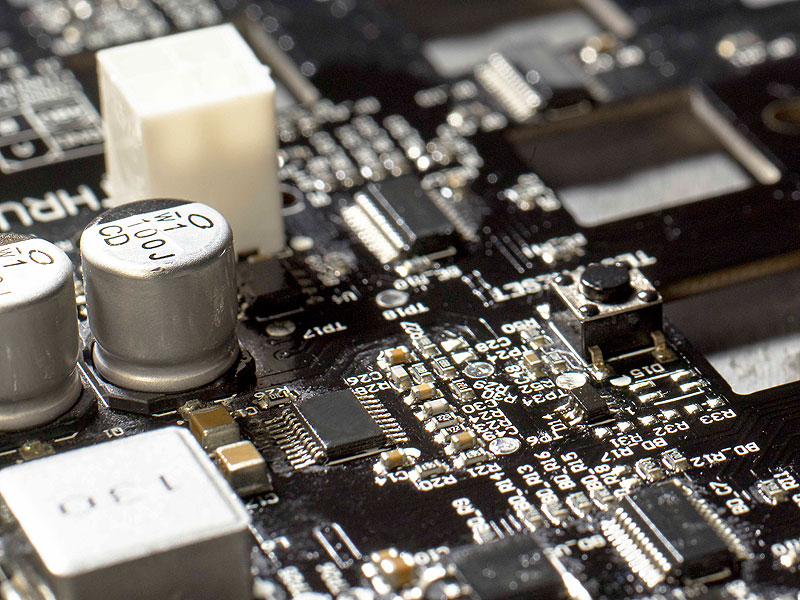

Why does an iPhone show defects after two years, while the display of a professional vacuum packaging machine easily lasts a decade? Electronics has two trends in development; one group with a shorter lifespan that creates a replacement market, and the group that is intended to last; focusing on longevity and reliability. RENA focuses on the second group, also referred to as embedded electronics.

For embedded electronics, the design phase is already focusing on preventing critical elements, but also on future problems regarding the availability of components. A long service life is not only determined by the design; it’s just as important to look at the availability of components over time. RENA takes second source components into account during the design phase, so that we are not dependent on only one manufacturer of a certain component.

Everything is possible ... or not?

We also use the expertise we have gained over the years, regarding products which are known not to change their range quickly. For example, we often get the question why a display can’t be bigger or cheaper. Consumers see these screens at low prices in telephones and tablets. The reason for this lies in the refresh rate of the original manufacturers of these phones and tablets. To be able to use a bigger or cheaper display, you should constantly go along with this refresh rate, because the manufacturers determine what is developed and produced. Thus affecting the availability of components through time. Our 40 years of experience ensure that we give accurate advice on these matters.

Determining factors

If we look at the design, there are a number of factors that determine the life of an electronic design. Before, during and after production, the product is subjected to a multitude of tests, quality requirements and inspections at RENA. Designs are produced under fully controlled conditions in our Smart Factory. The determining factors listed below play an important role in the service life of electronics.

• Heat management

Excessive heat development in a design can shorten the lifespan. Even a temperature that lies within - but towards the end of - the specs of a component will already limit the service life.

• Flow

Each component is specified with a maximum allowable current. Despite this specification, it is advisable to take a wide margin into account because high currents can cause internal damage.

• Mechanical load

Although nowadays a wide range of components is available in SMT technology, sometimes it is advisable to resort to THT components because of their greater mechanical load.

• Protection against moisture and chemicals

The most tricky external influences are liquids. The behavior of these liquids in electronics cannot be determined with certainty in advance. That’s why it’s advisable to apply a form of protection that is specifically tailored to the application.

• EMC (Electromagnetic Compatibility)

Electromagnetic radiation and conductivity can influence electronics. By taking this into account in the design and testing every aspect, it is possible to prevent these adverse consequences.

• Fire safety

A lot of applications will be used in situations in which it’s necessary that electronics continue to operate in case of fire. In addition, it is essential that the complete design (including housing) meets the requirements set for fire safety.

• Software

The core and driver software must be reliable in such a way that there are no bugs and/or no bugs can arise over time, even if there is an open network connection. Internet security is therefore also our top priority regarding driver software.

• Obsolete management

In every design, there will be a moment when a component becomes obsolete. By working closely with reliable suppliers, RENA receives a warning well in advance when a component will become obsolete, so that a last time buy can be agreed to buy time for essential redesign.

Arrive early in the route

When developing a new design, it’s important to determine the design specifications as early as possible in the process. That is why RENA is happy to advise you in the first phase, in which an new product idea is formed.

Want to meet?

Curious about our reliable custom made products? Or perhaps you want to know more about the possibilities for redesigning an existing product?

Don’t hesitate to contact our specialized team: +31-(0)76 - 599 5 995.