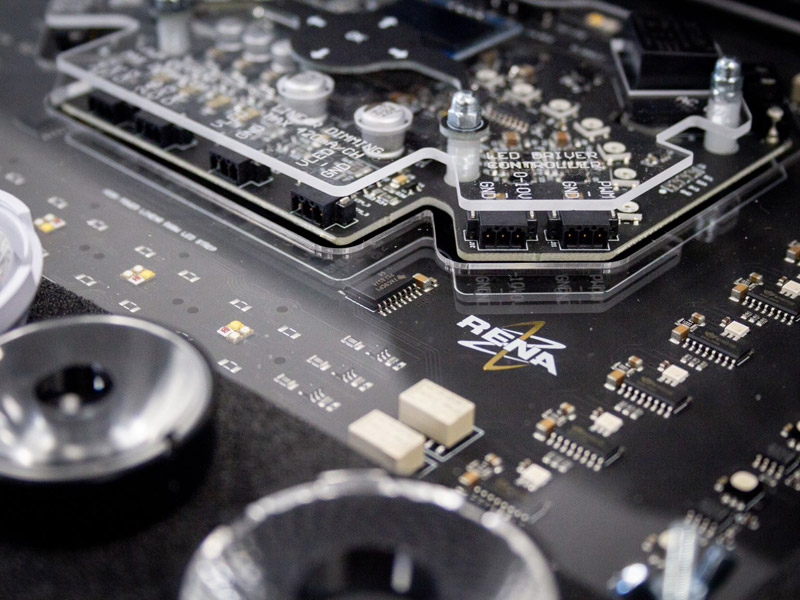

From a printed circuit board with LEDs to a fully assembled and certified luminaire; at RENA we make it all. There are plenty of steps to follow when we go from product idea to LED solution, such as choosing the perfect LED. Our LED Systems Architect Huub Borel and Business Development Manager Ebian Tempelaars will tell you more in this interview.

How do you make a choice for the best LED?

Huub Borel explains: "By listening carefully to the customer and to our own sales person, Ebian in this case. We really want to get to the bottom of the customer’s requirements. That’s why I consult directly with the customer in a lot of cases. If a customer lacks in-depth technical knowledge, I listen carefully to what they say and what they actually mean. For example, we regularly work with artists or designers who have a clear idea of what they want but cannot translate it into a technical specification. Not a problem at all, because we like to operate as a partner. We guide these customers throughout the entire process and ensure that they are unburdened in the technical field."

But experienced technicians also regularly gather around the drawing board at RENA. "It’s a fun challenge to turn these into satisfied customers," says Huub. "Everyone wants an efficient product that produces enough light, but the price must also match the customer’s specifications. That’s always an interesting puzzle for me. Being an independent supplier enables us to choose the best solution for the specific application, regardless of the component’s brand. I try to keep track of all existing leds. The file in which I run side-by-side comparisons contains around 8000 different leds.”

What specifications can RENA meet?

Huub fires away: "Countless specifications! From white to coloured LEDs, warm to cold white, indoor or outdoor. We also discuss whether or not the customer wants to use a lens, what the life expectancy is, whether the product must meet certain standards such as UL or DLC. We dive in deep before taking any further steps, and were always ready to provide professional advice. "

What kind of customers end up at RENA?

"These are mainly customers who do not have their own development and production capabilities," Ebian explains. "We have the knowledge of our own engineering department and all kinds of production possibilities in-house. It also happens that companies accommodate certain development and production at RENA for practical or business-economic reasons. We mainly work for OEMs (Original Equipment Manufacturers). "

"Many of our customers wishes are extremely specific. Logically, they end up at RENA, because parties with a higher technical level that offer a one-stop-shop concept like us are quite scarce. We only develop and produce custom-made products that are not available on the market. Most of our customers find us because they heard through the grapevine that we can offer them a high-quality solution. That's the best advertisement! "

Huub adds: "It also happens that a customer works with existing building blocks (for example Zhaga), but still wants to personalize part of the functionality. We’ll gladly get started on a design for these kinds of solutions, too. "

How did RENA become an expert on this?

"RENA has always been innovating and learning," explains Ebian. "We closely monitor what is happening in the market and regularly invite our suppliers here. We have invested in modern production means and can therefore produce high-quality products in an efficient manner. As a result, our placement costs have decreased over the years. "

Would you like to know more about the possibilities in custom LED lighting and electronics? Read more here or feel free to contact us.